Premium Labels and Tags

Give your brand the competitive edge it needs with precision-crafted, GMP-certified labels and tags.

Connect with a Consultant

Comprehensive Label and Tag Solutions

Tailored to Your Industry, Engineered for Excellence

As an experienced label converter, we offer a wide range of premium labeling options to meet your specific production, marketing, and regulatory needs.

From raw materials to finished products, our proven process and advanced print techniques ensure lasting performance with unbeatable production times.

Explore Products

Label Materials and Applications

Pressure-Sensitive Labels

Pressure-sensitive labels are versatile and easy to apply to a wide range of surfaces. We can convey vital safety information, communicate product features, and adhere your barcodes, QR codes, and variable data.

Brand Labels | Prime Labels

Reinforce your brand and make the right impression with high-quality brand labels, printed with precision and available in a variety of stunning specialty finishes.

Product Labels

Available in a variety of materials, including moisture- and heat-resistant options to help you maintain your FDA compliance. Ideal for food packaging, retail, pharmaceuticals, cosmetics, and much more.

Durable Labels for Harsh Environments

Built to withstand extreme conditions and essential for products exposed to moisture, chemicals, UV rays, and abrasion. Durable labels are ideal for automotive, electronics, and medical device industries.

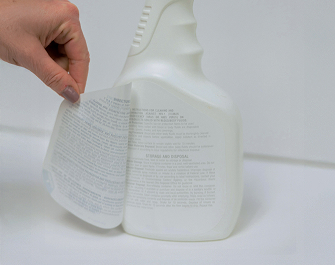

Extended Content Labels

We help you fit essential product information within the available space, allowing for compact, multi-layered content ideal for pharmaceutical, nutraceutical, chemical, and consumer goods applications.

- Single-Fold Labels – Perfect for ingredient lists, instructions, or multilingual packaging.

- Hinge Labels – Resealable for repeated access to critical product details without removing the label.

- Peel-and-Reveal Labels – A multi-layered solution for multilingual packaging, promoting other products, meeting industry requirements, and offering limited-time promotions or giveaways.

Variable Data Labels

Designed for applications that may require unique serial numbers, barcodes, or sequential information. High-resolution printing supports your efforts in inventory management, traceability, and security.

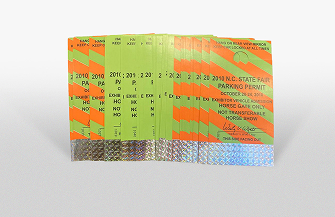

Cut and Stack Labels

Cut and stack labels offer high-quality printing, versatility across materials, efficient high-speed application, and durability for various environments.

Premium Finishing Options

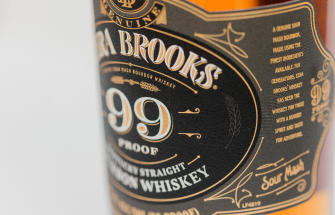

Foil Stamping

The shine of bright foils is a refined upgrade, giving an illusion of depth and a dramatic effect. Ideal for packaging fine wines, spirits, and luxury products.

Embossing

The raised design of embossing adds texture, dimension, and an upscale tactile experience. A popular choice for spirits or wine, specialty foods, personal care products, and gift packaging.

Specialty Coatings

Add UV coating to a label to enhance its visual appeal, improve durability, and create a unique tactile experience. Give your product a competitive edge while protecting its labels from wear, moisture, and fading.

- Gloss UV – A high-gloss coating that enhances colors and provides a vibrant, reflective finish for a sleek, premium look.

- Matte UV – A non-reflective coating that creates a smooth, sophisticated appearance while reducing glare.

- Soft Touch UV – A velvety, tactile coating that adds a luxurious feel to labels and packaging.

- Spot UV – A selective application of glossy coating to highlight specific design elements, creating contrast and visual impact. Adds subtle visual appeal and durability to premium branding materials.

- Tactile Varnish – A raised coating that adds texture and dimension to labels, enhancing both visual appeal and the sensory experience.

Lamination

Our lamination options protect and enhance your labels, improving durability with a clean finish. Choose from several finishes:

- Matte Finishing – A smooth, non-reflective finish for a touch of sophistication without glare.

- Gloss Finishing – A high-shine, vibrant finish for optimal color depth and a sleek appearance.

- Soft Touch Lamination – A velvety, matte finish that enhances labels with a luxurious feel while providing durability and scuff resistance.

- Thermal Transfer Printable – Advanced overlaminate designed to provide extra protection and durability when using a thermal transfer printer.

A Label Converter That Sticks

Your labels can be precise, fast, and compliant. Experience the difference of working with a label converter with a proven process, transparent communication, and rigorous quality for all your printing needs.

FAQs

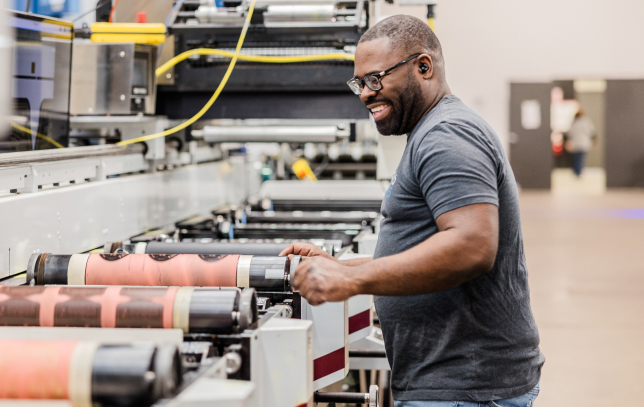

What is flexographic printing?

Flexographic printing (or flexo printing) is a rotary printing method that uses flexible relief plates to transfer ink onto a variety of substrates, making it ideal for high-volume label and packaging production.

What are pressure-sensitive labels?

Pressure-sensitive labels (PSLs) are self-adhesive labels that stick to surfaces when light to moderate pressure is applied. They don’t require heat, water, or solvents to activate the adhesive—just simple pressure. These labels are made up of multiple layers, including a face stock (the printed surface), an adhesive layer, and a backing liner that protects the adhesive until application.

How does flexographic printing work?

Flexographic printing (or flexo printing) is a high-speed, roll-to-roll printing process commonly used for pressure-sensitive labels, packaging, and other flexible materials. It uses flexible printing plates made of rubber or photopolymer, which are wrapped around rotating cylinders.

What are the advantages of flexographic printing?

Flexographic printing is a great solution with many advantages, including:

- High-speed production

- Cost-effectiveness for large runs

- Ability to print on a wide range of materials

- Ability to accommodate various inks, including water-based and UV-curable inks

- Ability to print continuous patterns (e.g., wallpapers, gift wraps)

What materials can be used for flexographic labels?

We can use numerous materials for flexographic labels, including:

- Paper (coated and uncoated)

- Films (BOPP, PET, PE, PVC)

- Foils

- Laminates

How does flexo printing compare to digital printing?

Flexo printing is more cost-effective for large runs, offers a wider range of material compatibility, and has faster production speeds. Digital printing, on the other hand, is better for short runs, variable data printing, and detailed color work without requiring printing plates.

What industries use flexographic labels?

Many industries make use of flexographic labels, including:

- Food and beverage

- Pharmaceuticals

- Cosmetics and personal care

- Industrial and chemical labeling

- Retail and logistics

What types of inks are used in flexo printing?

We use three different types of inks for flexo printing:

- Water-based inks

- Solvent-based inks

- UV-curable inks

What are common quality issues in flexo printing, and how are they resolved?

With quality as one of our top priorities, we are familiar with addressing common quality issues in flexo printing.

- For dot gain (excessive ink spread), adjust ink viscosity and pressure.

- For misregistration (misaligned colors), ensure proper plate mounting and press calibration.

- For ink smearing or ghosting, optimize drying systems and ink formulations.

What factors influence the cost of flexo labels?

The cost of flexo labels is influenced by the following factors:

- Material type

- Ink colors used

- Label size and shape

- Special finishes or embellishments

- Print volume (higher quantities typically reduce unit cost)